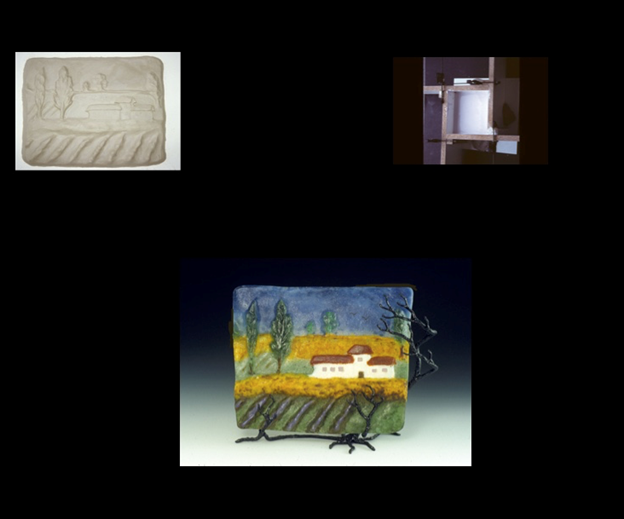

Bellevue Arts Museum show Making our Mark Art by Pratt Teaching Artists, A Legacy at 40 is a commemorative exhibition. Show was November 10 to April 8, 2018. Forget Me Not is my piece selected for this exhibit. I have been teaching pate de verre at Pratt from 2001 to date.

Pâte de Verre is French for “paste of glass:. This term originated in France at the end of the 19th Century to describe a technique of glass discovered by Egyptians and possible influences from China and their purple and blue hard glazes. The Egyptian’s developed a sintered-quartz ceramic that was glazed by firing. Later they developed a harder more crystalline compound called Egyptian blue harder than it’s more porous faience counter part. While the true origin is unknown scientific laboratories are researching the influence the Egyptians used to make artifacts for the Pharaohs.

Archeologists from France came across Egyptian Blue and were intrigued by the glass and the iconic use of their research from the tombs of pharaohs. It peaked the interest of ceramists in the industry such as Henri Cros (b1840 – d1907). Cros had an interest in experimentation and his love of getting painterly effects lead him to a life of sculpting and glass making. During the Art Nouveau period glassing making for vessels and sculptures were being rediscovered and refined. All glass casting in a kiln was termed pâte de verre but in modern times it’s be redefined by methods of Hot Casting (ladle poured) vs. Kiln Casting.

Modern pâte de verre uses a sintered method (a tack fuse), or high temperature firings to create different looks. From single to multi-part molds you can use plaster-silica, ceramic fiber, press molded, drip molded using sculpted models in wax or clay.

To get the polychrome colors various frits and powders are used with a glue binder (CMC, Gum Arabic, Aloe Vera). Glass colors employ various colorants, which can cause reactions. Glass manufacturers publish which color interacts with another color so you can use or avoid the reaction. Lots of glass secrecy fell away in modern times with the understanding for the chemistry of glass. It is my reason for teaching so this art form is not lost in history again and new artists push the boundaries of what’s possible.

The first sintered method of pâte de verre uses glass the size of sugar and powder and is packed into a plaster-silica mold and kiln fired to a tack fuse texture known as sintered.

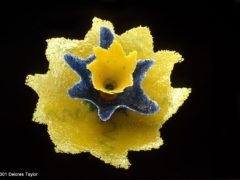

Rather then using a plaster silica mold and talc as an inner core, this method uses a ceramic fiber mold and no inner core. This creates a sugar crystal effect on the outside of the piece and a shiny texture on the inside of the piece.

“Mars” (c) Artglassconcepts.com

Pâte de Verre is French for paste of glass. This term originated in France at the end of the 19th Century to describe a technique of glass discovered by Egyptians and possible influences from China and their purple and blue hard glazes. The Egyptian’s developed a sintered-quartz ceramic that was glazed by firing. Later they developed a harder more crystalline compound called Egyptian blue harder than it’s more porous faience counter part. While the true origin is unknown scientific laboratories are researching the influence the Egyptians used to make artifacts for the Pharaohs.

Archeologists from France came across Egyptian Blue and were intrigued by the glass and the iconic use of their research from the tombs of pharaohs. It peaked the interest of ceramists in the industry such as Henri Cros (b1840 – d1907). Cros had an interest in experimentation and his love of getting painterly effects lead his to a life of sculpting and glass making. During the Art Nouveau period glassing making for vessels and sculptures were being rediscovered and refined. All glass casting in a kiln was termed pâte de verre but in modern times it’s be redefined by methods of Hot Casting vs. Kiln Casting.

Modern pâte de verre uses methods of sintered (a tack fuse), high temperature firings to create different looks. From single to multi-part molds you can use plaster-silica, ceramic fiber, press molded, drip molded using sculpted models in wax or clay.

Ahowcasing amazing female artists who inspire me. I first ran into her work on a trip to the UK. Lucie Rie fled Nazi Vienna in 1938 for London. Read this amazing article on Lucie Rei at craft and culture’s blog. Not only a pioneer in ceramics but a courageous woman who fled Vienna as it could be toxic for a young woman in the arts. She was direct and would not be silenced, self-confident but did not grandstand. Her sense of objects of beauty surrounding your world was a design conscious standard in her work. She was born March 16 1902.

First I decide how the piece will be mounted, which impacts the design. I will either use a plaster hump mold or hand build the clay. Use of rails provide a even thickness of the clay. I have found this impacts both the firing and the final look of the product.

Once you have completed making your clay or wax models secure it to a melamine board. Center the model in the middle of that board. Make sure you have a large enough board around your model to accommodate the 2-3 inch gap plus the coddles then space to secure the outside of the coddle to prevent leaks. The larger your piece becomes the more the mold needs to be thicker and you increase the depth and the size of the coddles proportional to the size of the model.

Using quick grips or C-clamps and I pinwheel them around the piece. Use snakes of clay to secure the inside walls around the base and up the wall. Then 1-2 inch thick snakes on the outside of the coddle at the base to insure the plaster does not leak out. If you use a 2″ mold thickness then mark the highest portion of the model and add 2-2.5 inches, mark with a pencil to give you a visual pour level reference and to keep the mold uniform in size for firing purposes. 3″ molds you add 3 inches, etc.

Then prepare your plaster silica mix for the face coat and a plaster silica additive as your back up coat. Pour into the corner of the coddle allowing the plaster to raise to the reference line. Gently shake without moving the clay to remove any excess bubbles then let sit for 40 minutes. This step use great caution to prevent blow outs of plaster from your coddle.